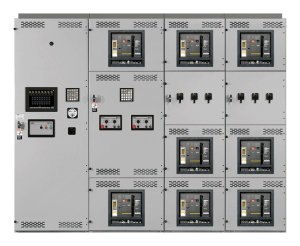

The ASCO 4000 Series Generator Paralleling Switchgear can start, synchronize, parallel, monitor and protect emergency, standby, and prime power systems. 4000 Series Generator Paralleling Switchgear power management provides the most powerful, reliable and advanced digital control by separating the control of generators from load distribution control, and independently managing each.

The ASCO 4000 Series Generator Paralleling Switchgear can start, synchronize, parallel, monitor and protect emergency, standby, and prime power systems. 4000 Series Generator Paralleling Switchgear power management provides the most powerful, reliable and advanced digital control by separating the control of generators from load distribution control, and independently managing each.

Generator load demand maximizes the efficiency of generator usage. After a stabilizing time delay, a generator may be started and connected to the main bus for high demand, or unloaded and shut down for low demand. This conserves fuel and reduces maintenance requirements by operating fewer generators at a more efficient level. Bus load optimization determines the capacity for adding loads to the bus. It evaluates system utilization, based on available capacity and distribution load ratings.

Effective power management derives from the assignment of unique and structured priorities to distribution loads, which are controlled by the 4000 Series Generator Paralleling Switchgear via transfer switches and/or electrically operated distribution circuit breakers. Because the 4000 Series Generator Paralleling Switchgear can control up to 32 individually prioritized transfer switches, individually controls each transfer switch per its unique priority, and allows operators to change priorities run-time, the ASCO 4000 Series Generator Paralleling Switchgear provides unsurpassed distribution control.

ASCO 4000 Series Generator Paralleling Switchgear Features

- One-line screen for familiar representation of site installation

- Optional remote color touch screen

- Ethernet communications with Modbus mapping for external system connectivity (CPMS, DCIM, BMS)

- Engine-generator status/control screen

- Generator trending with auto-scale plots

- Historical Alarm

- ASCO transfer switch controller and metering connectivity including remote test capability

- System metering and individual generator metering screens

- Security features including multiple security levels and individual operator accounts

- Pre-Engineered configurations for reduced lead time

ASCO 4000 Series Generator Paralleling Switchgear Specifications

| System Voltage | 600V |

| Max. Number of Generators | 4 (Up to 8 depending on configuration) |

| Standby/Isolated Bus | Yes |

| Prime Power | Yes |

| Main Bus Amp size available | 2000 to 10000 A (Type 1 Enclosure) 2000 to 6000 A (Type 3R Enclosure) |

| Switchgear Standard | UL 1558 |

| Bus Bracing Level | 100 KA or 200KA |

| Overhead Rail Lift | Optional for Type 1 Enclosure |

| Seismic Certification Option, SDS | 2.46 (Includes rooftop installation) |

| IBC 2012 & OSHPD | Included with Seismic Certification Option |

| Master Controls Touch Screen | 10” (Standard)/ 15” (Optional) |

| Redundant Master Touch Screens | Optional (Up to 2 Additional Color Touch Screens) |

| NFPA 110 Generator Monitoring | Yes |

| Master PLC | Yes (GE RX3i or Allen-Bradley ControlLogix) |

| Redundant Master PLC | Optional |

| Hardwired Manual Paralleling | Standard |

| Bus Load Optimization | Standard |

| General Load Demand | Standard, Includes Soft Generator Unloading |

| Load Shed/Add | ATS or Electrically Operated Circuit Breaker |

| Number of ATS’s (Manually Operated Distribution CB) | 1 – 32 |

| Number of ATS’s (Electrically Operated Distribution CB) | 1 – 16 |

| Simulator for Testing and Training | Optional |

| Generator Paralleling Breakers | 1 or 2 per cubicle (Depending on Options) |

| Max. Generator Breaker Frame Size | 3200 A (2) 5000 A (1) |

For more in-depth specifications, see the data sheet.

For more information about ASCO Products,

call 86 21 5859 8677 or email sales@alphaenertech.com.