Static UPS vs Rotary UPS are common terms used to describe two different UPS system designs. Static UPS, or an electrically coupled UPS, versus a Rotary UPS or mechanically coupled UPS. Each provides certain benefits for different applications.

Static UPS vs Rotary UPS are common terms used to describe two different UPS system designs. Static UPS, or an electrically coupled UPS, versus a Rotary UPS or mechanically coupled UPS. Each provides certain benefits for different applications.

A UPS is designed to provide power when utility power goes out. The UPS takes the load temporarily until power is restored, or a generator turns on and powers the load. You can classify a UPS according to how the energy storage system is coupled to the rest of the system and differentiate them by several factors, including how they handle tough anomalies such as voltage swings, large step loads and short-term outages. Here, we will examine the two methods of coupling, electrically and mechanically, to compare performance, flexibility, reliability, availability, and maintainability.

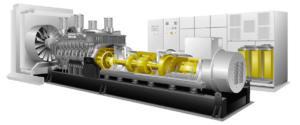

A Mechanically Coupled UPS connects the energy storage system to the UPS using a common mechanical drive shaft for both charging and discharging. In a mechanically coupled UPS, a generator is direct coupled with an energy storage system rotating on a shaft. The generator rotates at synchronous operating speed and the energy storage system at a much higher speed. When power is lost, the energy storage system transfers power to the load mechanically via controlled braking. The most common form of a mechanically coupled UPS is commonly referred to as a DRUPS, Diesel Rotary Uninterruptable Power Supply, in short, a Rotary UPS. Rotary UPSs are generally used in applications over 1MW and when several of the following conditions exist:

- Applications that require an engine generator and UPS and there is limited space

- Industrial applications where the majority of the loads are mechanical, multiple motors are constantly turning on and off (multiple, short duration inrush currents)

- Typically installed either outside of the building or within a specially built enclosure

- Satellite stations and broadcast stations where high power amplifiers turn on and off in rapid and random sequence

- High security, military installations

- Nature of the load demands the highest-quality sinusoidal waveform or there is a downstream requirement for system fault clearance without having to by-pass directly to utility power

- Environments where it is very expensive to provide air conditioning

An Electrically Coupled UPS connects the energy storage system to the rest of the system via a DC link and utilizes power semiconductor devices (IGBTs) to control the flow of electricity during charging and discharging. Batteries, flywheels, or ultra-capacitors are used as the short-term energy source. There are two types of electrically coupled UPS. The first, commonly referred to as a Static UPS, uses fast switching power semiconductors (IGBTs) to fabricate a basic waveform which is then filtered by power capacitors to create an AC sine wave. Static UPSs are used in most applications and are the most widely adopted (95.7% of the market according to IHS Markit) because of their comparatively low installation cost, flexibility, and efficiency. Modular architectures offer flexibility in sizing and scaling to meet demand.

The second electrically coupled UPS, which has unique low-distortion and high fault clearing characteristics, uses more rugged circuitry with power semiconductors that switch at a slower speed to produce a basic waveform which is then filtered using a synchronous generator in place of power capacitors to produce an AC sine wave. This is referred to as an electrically coupled motor-generator rotary UPS. Electrically coupled motor-generator rotary UPSs are generally used in applications over 1MW and in several specialized circumstances such as:

- Isolation of harmonics between the load and the mains, frequency stabilization during transients or load changes

- Industrial applications where the majority of the loads are mechanical, multiple motors are constantly turning on and off(multiple, short duration inrush currents).

- Harsh environments and remote conditions

- Semiconductor production – Wafer fabricators, Photomask design, degaussing systems

- Manufacturing, industrial automation – Pharmaceuticals, Food & Beverage, Oil & Gas, Automotive, Aluminum, Cement, Petrochemicals, Textiles, Trans-continental cables

- Energy (applications that require Bi-directional power flow) – Renewable energy generation, Co-generation, Micro grids, Smart grids

- Oil & Gas – Oil and gas field infrastructure, Trans-continental gas pipelines

- Broadcasting & communications – Satellite and broadcast stations

Mechanically Coupled UPS Benefits

- Peak efficiency in on-line mode

- Superior handling of Inrush currents

- Harsh environment tolerant

- More suitable for high power applications.

- Improved reliability with the elimination of capacitors

- Smaller footprint

Electrically Coupled UPS Benefits

- Better operating efficiency at low load (3% difference at <=25%)

- Scalable architecture

- Multiple energy storage options

- Lower maintenance requirements, improved availability, and lower operating

- UPS and emergency generator are independent of one another and can be configured differently to suit requirements and physical constraints

Additional Benefits of Electrically Coupled Motor-Generator Rotary UPS

- Elimination of capacitors and fans increasing availability

- High efficiency at 35% load

- Large capacity units, reduced footprint

- Better overload and fault characteristics

- Available for low and medium voltages

- Bi-directional power flow for feeding energy back to the grid

When exploring UPS systems for your facility, what’s important is to understand the specific application and associated power quality issues that exist. Then select the best suited classification of UPS, electrically or mechanically coupled along with an energy storage system that meets the desired economical, performance, flexibility, reliability, availability, and maintainability criteria.

For more information about Static UPS vs Rotary UPS,

call 86 21 5859 8677 or email engineering@alphaenertech.com.